Browse Information By:

FiberROC Manual

The FiberROC Manual is an additional kit

provided together with the HydROC hydrolysis unit. The FiberROC Manual can

facilitate Crude Fiber determinations according to the Weende method, using the

unique OPSIS LiquidLINE Crude Fiber bags. The unit can also be used for

Hydrolysis, when removing the Crude Fiber kit from the instrument.

ICP fusion

In an ICP fusion solution

the machine is configured to pour the molten flux directly into the acid

digestion. The custom machine can be configured to be an ICP only model or a

hybrid solution capable of meeting ICP and XRF fusion requirements

simultaneously. This is particularly useful for the laboratory that requires a

high variety of samples to be produced on an ongoing basis.

Modutemp Shaking Fusion Furnace

For high volume

bead-making requirements, XRF Scientific’s six-place, electric fusion machine

offers solid reliability with ease of installation and operation. These

machines are capable of producing up to 30 fused beads per hour, per machine,

with all functions accurately controlled and timed. Many laboratories have

found that one operator can easily run two of these units simultaneously.

Mouldable Fusion

The Mouldable machine uses

a mould which incorporates a crucible shape in which both mixing and moulding

is performed. When mixing is complete, the molten material is cooled in the

mouldable and the bead is then removed using a suction cup or similar. This

application is suitable for high throughput environments where the impact or

importance of labware lifetime is secondary. If you are interested in a

custom solution please contact us so we can determine how best to meet your

specific requirements.

Phoenix GO SERIES GAS FUSION MACHINE

Phoenix Go Line

is designed for the preparation of fused glass disks (XRF) and solutions (ICP).

It‘s also used for fusions with carbonates or peroxides.

Phoenix VFD GAS FUSION MACHINE

For low

contamination, cold to cold operation at high throughput, XRF Scientific’s

Phoenix range of gas fusion machines are the perfect solution. When it comes to

complex fusions, particularly where they are being conducted for the first

time, being able to see the chemical process as it evolves in the crucible is

of great benefit to the experimentalist. It is also of great benefit in

preserving platinum ware and the life of your machine.

The Phoenix

allows you to add ammonium iodide at just the right time in the process in a

repeatable and controllable manner. Additional features include the ability to

vary the cooling rate to find that delicate balance between cracking and

crystallisation and ensure all pre-oxidation has occurred with a two stage

heating process.

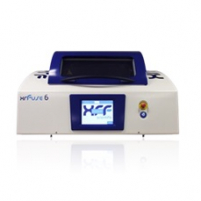

XRFuse

The xrFuse range of automated electric fusion machines allow seamless sample preparation of glass beads for XRF and ICP

solutions in a matter of seconds. Designed with the latest thermal imaging

technology, consumer tested in the biggest XRF laboratories in the world.

Instrument features include zero contamination, process flexibility, simple

user interface, and safe operation. The unit is cold-to-cold, fully CE

certified. Different models for varying throughput requirements are available.

Key Features:

- Zero contamination

- Safe cold to cold operation

- Process visibility

- Temperature range to 1250C

- 24 programmable recipes